POWER SOURCE

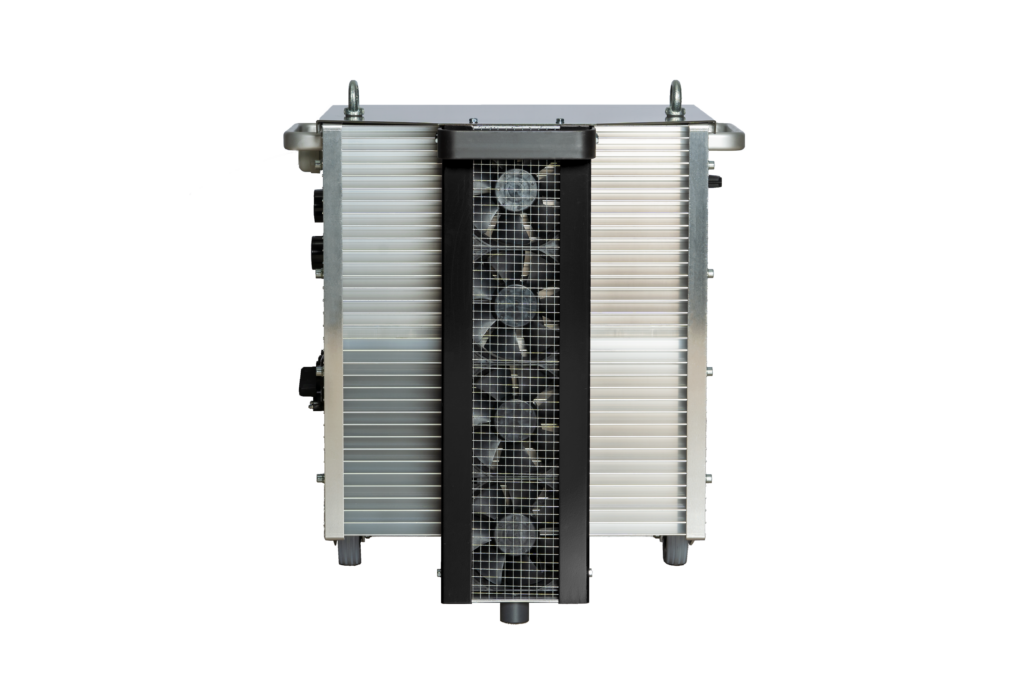

LSQ6

The energy bundle

The LSQ6 is the logical further development of the LSQ5, with a fresh look and the usual robust technology. The LSQ6 is a platform for different product variants with optional integrated control and optional integrated interface. The LSQ6 with Direct Control Technology (DCT) guarantees a power supply that is optimally matched to the welding process. Contrary to conventional inverter power sources, Direct Control Technology regulates electricity directly according to the requirements of the welding process without a fixed cycle frequency. Energy required for the process is precisely supplied without delay. A central processor continuously analyzes the welding process and current/voltage values and uses the data obtained to ensure precise fine-tuning in order to optimally control the power section. The result is high efficiency, which benefits heat generation. The LSQ6 can be overloaded, is extremely robust and can be used worldwide.

LSQ5

The energy bundle

With 420A and Direct Control Technology (DCT), the LSQ5 ensures an energy supply that is optimally matched to the welding process. Contrary to conventional inverter power sources, Direct Control Technology regulates electricity directly according to the requirements of the welding process without a fixed cycle frequency. Energy required for the process is precisely supplied without delay. A central processor continuously analyzes the welding process and current/voltage values and uses the data obtained to ensure precise fine-tuning in order to optimally control the power section. The result is high efficiency, which benefits heat generation. The LSQ5 is overloadable, extremely robust and can be used worldwide.

LSQ3

The small power pack

The LSQ3 is an optimal entry-level solution with 340A and Direct Control Technology (DCT). Contrary to conventional inverter power sources, Direct Control Technology regulates electricity directly according to the requirements of the welding process without a fixed cycle frequency. For joining tasks, e.g. on car body panels and exhaust systems, the LSQ3 offers sufficient power reserves, especially with the characteristic curves adapted to the medium and thin panels segments.