INTERFACES

Interfaces, links between our welding systems

and robots or production lines

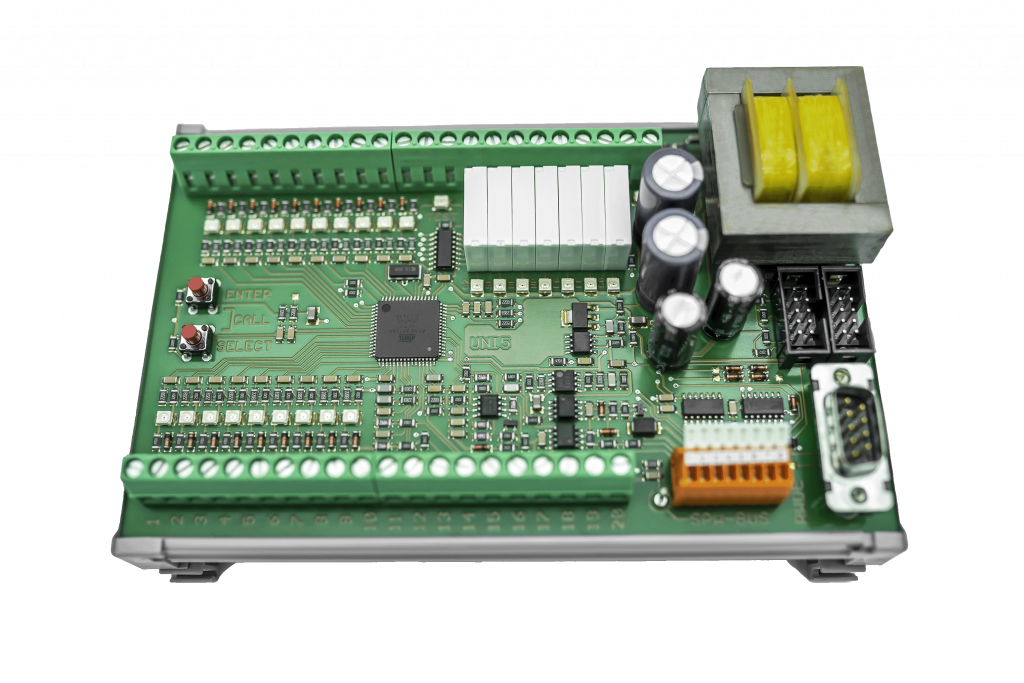

UNI 5

The UNI 5 is the optimal interface

Some robots or production line PLCs use digital I/O, analog signals or a serial interface to talk to other machinery. The interface UNI 5 translates such signals to be used by our welding systems. Through different configurations, a variety of digital encodings, analog signals or serial protocols can be used to control our welding system. Robot-Welder-Data-Exchange (RWDE) is a system integrated into UNI 5 to control up to four of our welding systems via a single serial port. UNI 5 comes preconfigured for the customers configuration needs but can be reconfigured by the customer afterwards without additional hardware or software.

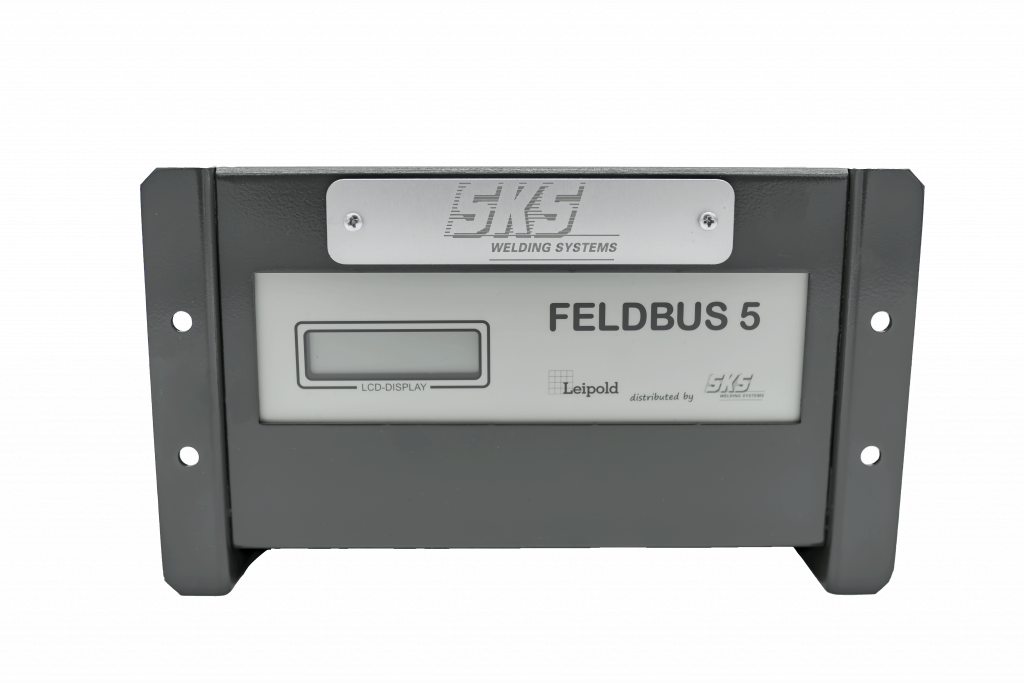

FELDBUS 5

The Feldbus integration

Feldbus 5 is an interface designed for integration into fieldbus based production lines. It connects our welding systems to a variety of different fieldbus types. It additionally has five digital inputs and five digital outputs for locally connected auxiliary devices such as a local torch cleaning station. Data transmission in fieldbus networks allows a much more detailed representation of our system in the higher-level production system than is possible with UNI 5. Thus, simultaneous transmission of many actual values and presetting of many setpoint/correction values can be implemented, which would otherwise require many times the inputs/outputs of a UNI5.