INTERFACES

Interfaces, connections of our welding systems with industrial robots and production systems

FELDBUS 6

Feldbus integration

The FeldBUS6 interface is designed for integration in feldbus-based production systems and can connect our welding systems to many different types of feldbus. It also has eight digital inputs and eight digital outputs for exchanging signals with the local environment, such as a local burner cleaning station. Compared to the Feldbus 5, the FeldBUS6 halves the latency time with which measured values are available for the customer’s system. Data transmission in feldbus networks enables a much more detailed representation of our system in the higher-level system than is possible with UNI 5 or Feldbus 5. This makes it practical to simultaneously transmit many actual values and specify many setpoint/correction values, which would otherwise require many times more inputs/outputs than a UNI 5.

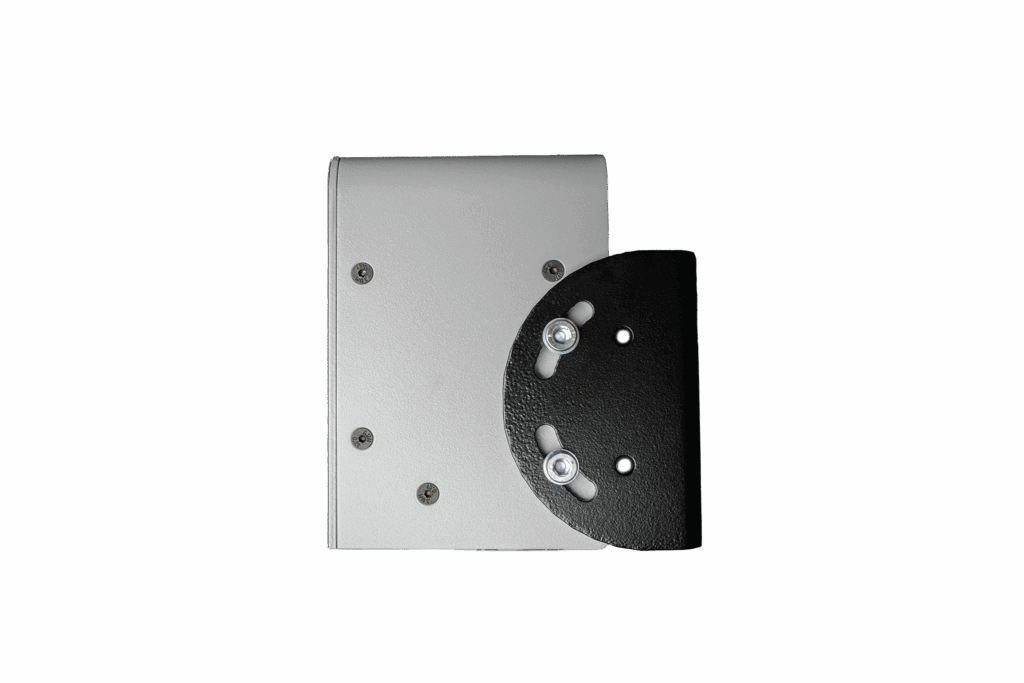

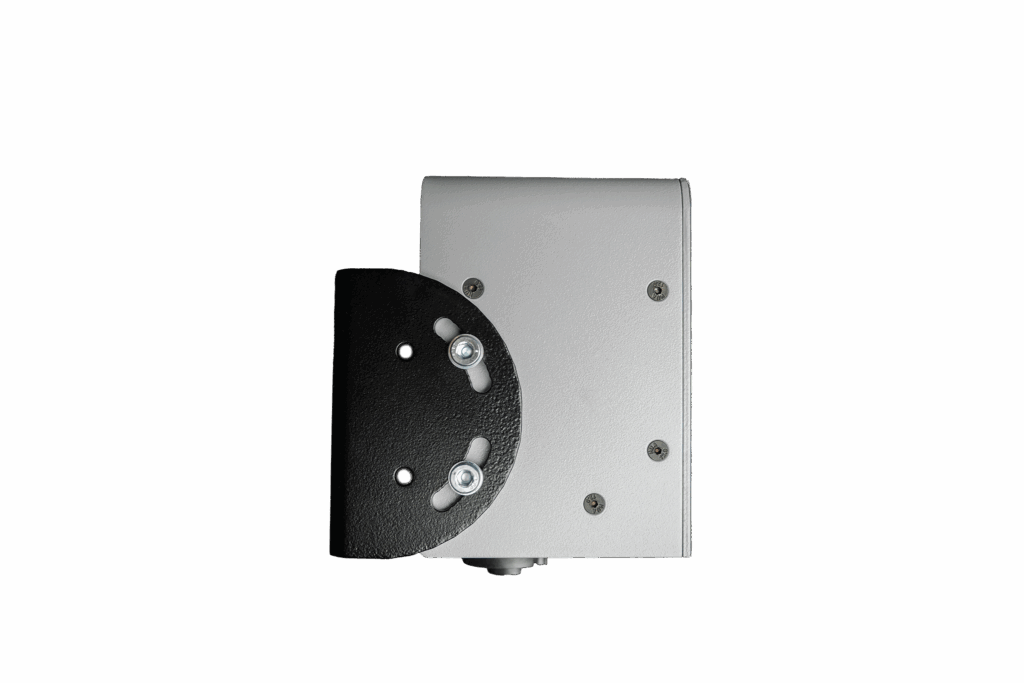

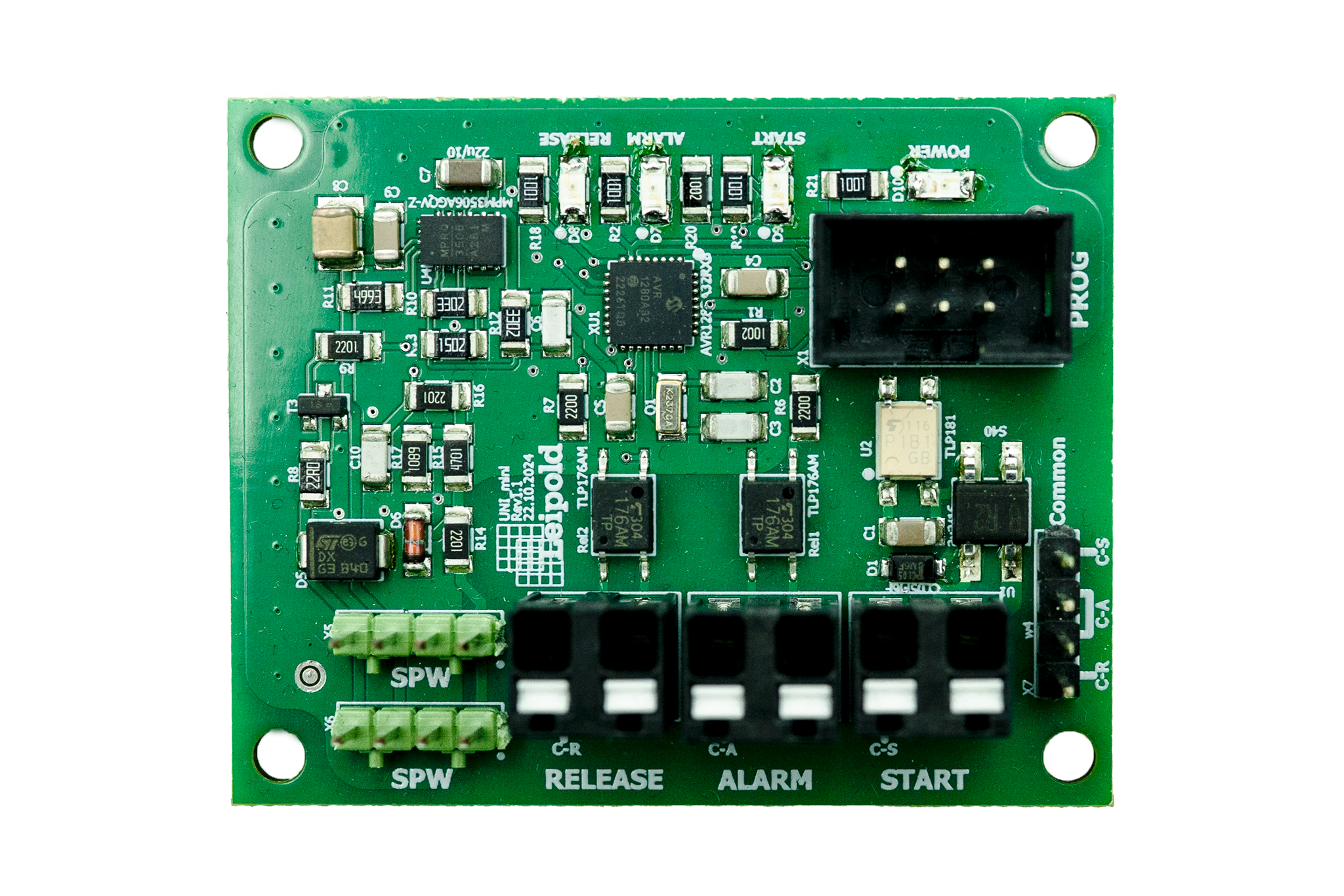

UNI Mini

Interface for semi-automatic machines

The UNI Mini is a cost-optimized robot interface, limited to what is absolutely necessary, for connecting semi-automatic machines to our system. It has one digital input (start) and two digital outputs (enable, alarm), nothing more.

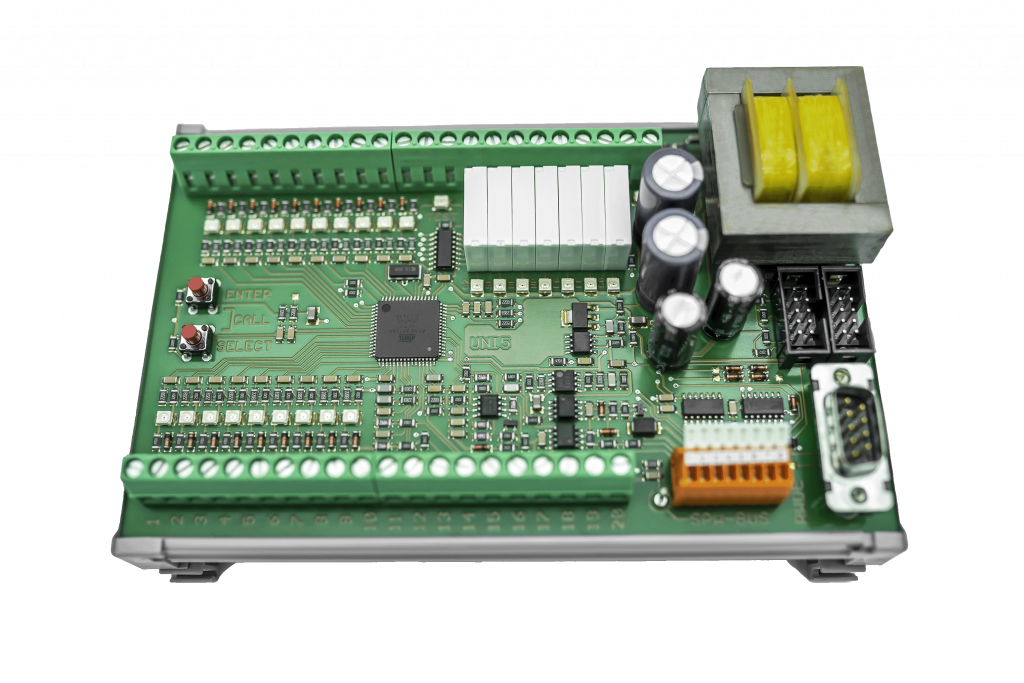

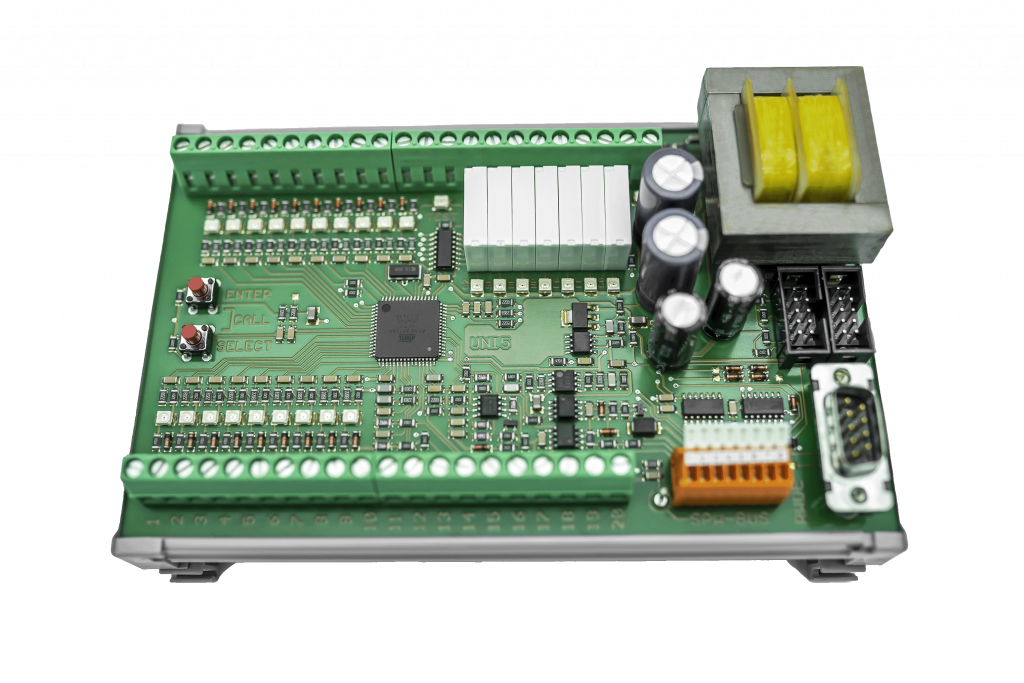

UNI 5

The UNI 5 is the optimal interface

Some robot or system controllers use digital inputs/outputs, analog signals or serial interfaces to communicate with their environment. The UNI 5 interface can convert such signals for our welding systems. Through different configurations, a variety of digital coding, analog signals or serial protocols can be used to control our welding system. With the Robot Welder Data Exchange (RWDE) integrated in UNI 5, up to four of our welding systems can be controlled via a single serial interface. The UNI 5 is specially configured for the control type used in welding systems and robots before delivery and can be reconfigured by the user at any time without additional hardware or software.

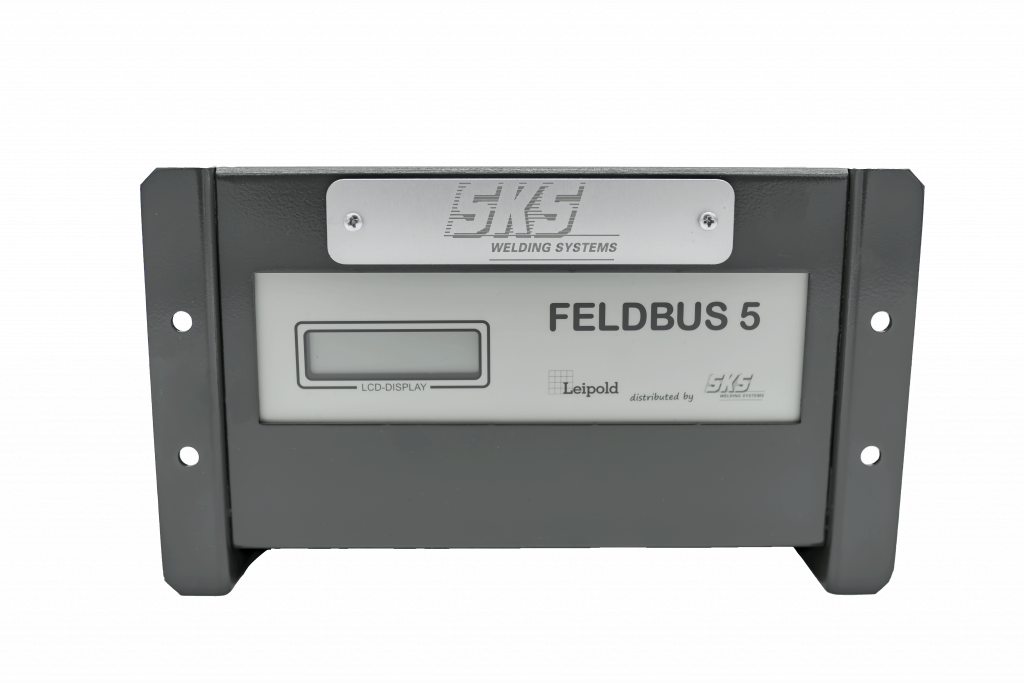

FELDBUS 5

Feldbus integration

The Feldbus 5 interface is designed for integration in feldbus-based production systems and can connect our welding systems to many different types of feldbus. It also has five digital inputs and five digital outputs for exchanging signals with the local environment, such as a local burner cleaning station. Data transmission in feldbus networks enables a much more detailed representation of our system in the higher-level plant than is possible with UNI 5. This means that simultaneous transmission of many actual values and specification of many setpoint/correction values can be practically implemented, which would otherwise require a multiple of the inputs/outputs of a UNI 5.