CONTROLS

Welding process controls,

Communication talents.

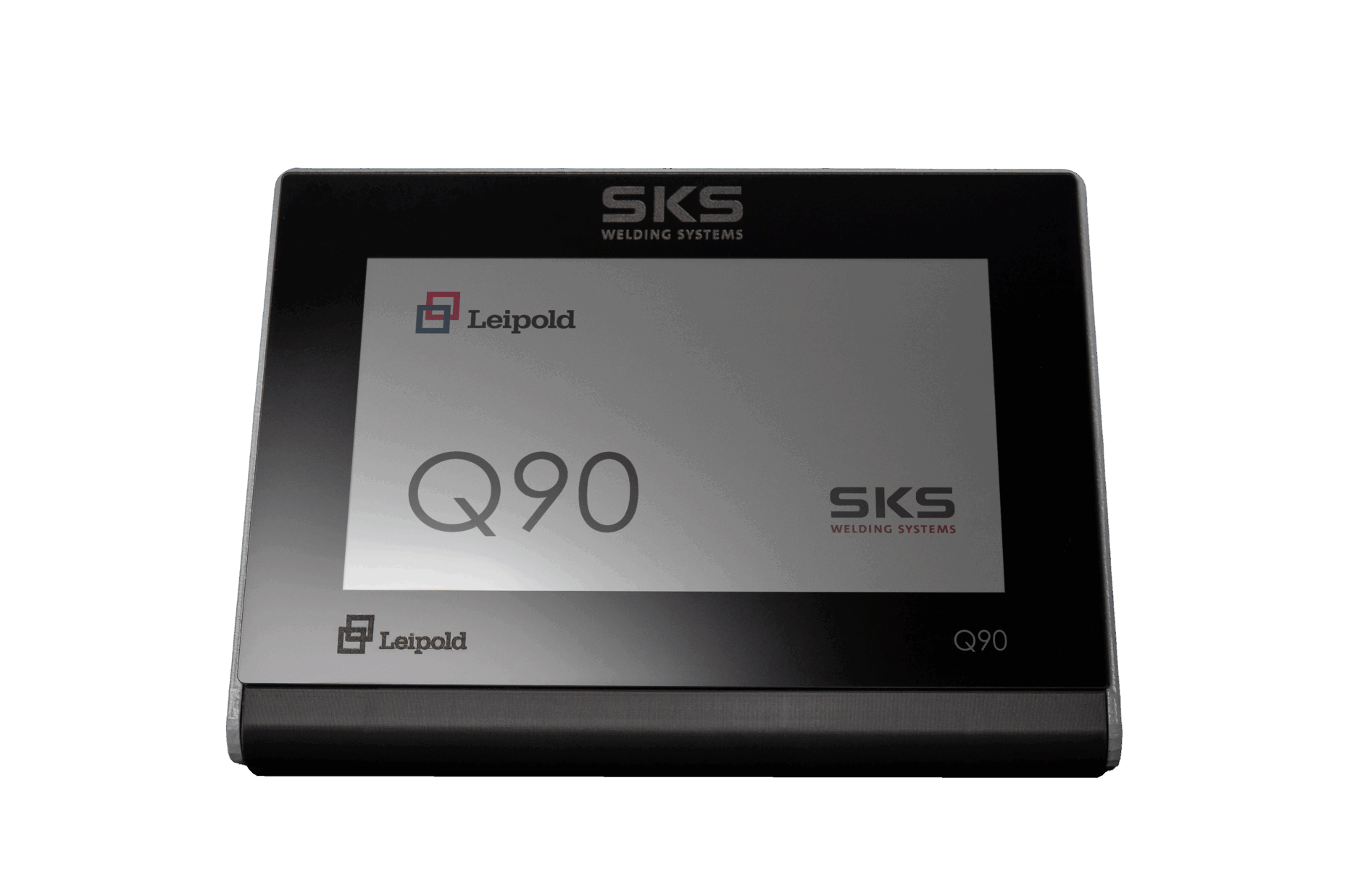

Q90

Universal control with multi-touch screen

The Q90 enables the central control of a welding system and provides the interface between man, PC and welding system. With its touch screen and innovative operating concept, the Q90 is clear and easy to operate. The Q90 has an integrated, flexible fieldbus interface for all common fieldbus types. Compared to our Q80, the Q90 calculates more than twice as fast, has four times the memory, a capacitive multi-touch display and an integrated fieldbus interface. Our control units calculate optimum parameters for welding processes according to basic data such as material, filler material, wire feed speed and gas type. The Q90 can handle various welding processes (I-pulse, MIG/MAG, U-pulse, KF-pulse, microMIG, MMT-X, TIG, TIG-pulse, cold wire) with automatic tracking of the welding parameters (AutoComp) in the event of changes in the environment, such as position errors of the welding torch, temperature fluctuations, draughts, etc. In combination with robots, for example, the Q90 can automatically adapt the welding parameters to the path speed of the welding process (SynchroWeld). With its Ethernet interface, the Q90 takes over the communication of our system with the outside world. With our PC software Q8Tool, centralised or decentralised data management and seamless welding data recording are guaranteed. The Q90 is fluent in MQTT and OPC-UA. With an optional license, the Q90 can record welding data completely internally and transfer it to our Q8xRemote visualization software.

Q1-O

Manual welding control

The Q1-O welding process control is the further development of the Q1 with a high-contrast OLED display and glove-compatible rotary knob. The Q1-O is designed for durability and easy reproducibility. It is designed for manual welding tasks with Leipold power sources (LSQ). Our control units calculate optimum parameters for welding processes according to the specification of basic data such as material, filler material, wire feed speed and gas type. The Q1 masters various welding processes (I-pulse, MIG/MAG, U-pulse, KF-pulse, TIG, TIG-pulse with automatic tracking of the welding parameters (AutoComp) in the event of changes in the environment, such as position errors of the welding torch, temperature fluctuations, draughts, etc.).

The setup and data backup are simplified by our Q1-Tool software.

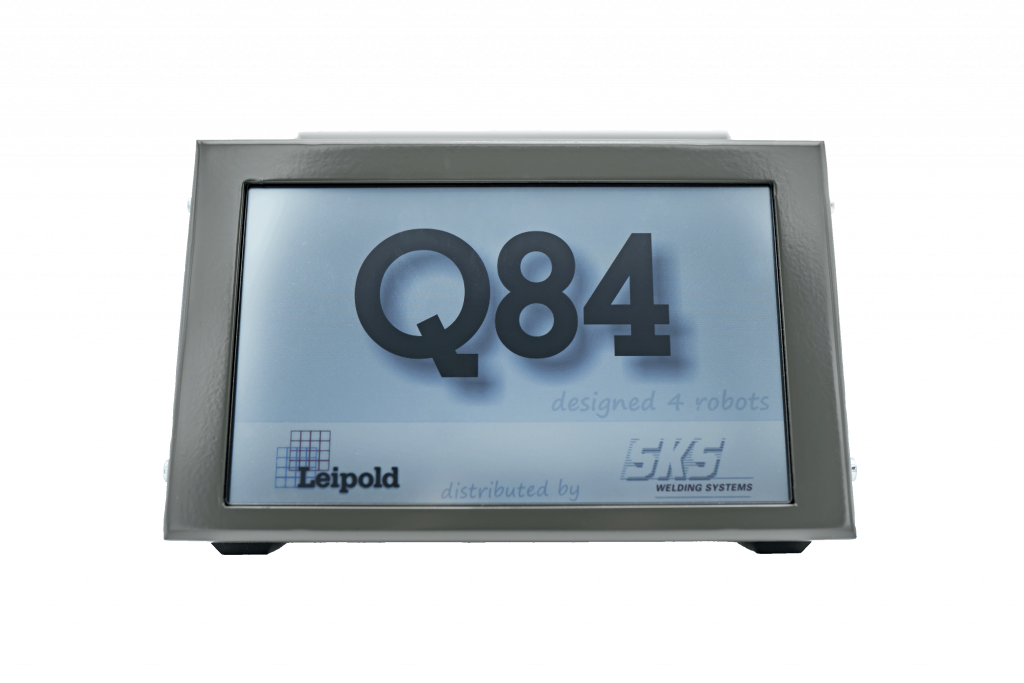

Q84r

Q84s large and fast

The Q84r enables central control of four welding units and provides the interface between man, computer and welding equipment. It has identical functions to the Q84s, but has a larger screen and is able to be equipped with faster processors. With its touch screen and innovative operating concept, the Q84r is clear and easy to use. Our control units calculate optimal parameters for welding processes according to the specification of basic data such as material, filler metal, wire feed speed and gas type. The Q84r masters various welding processes (I-pulse, MIG/MAG, U-pulse, KF-pulse, microMIG, TIG, TIG-pulse) with automatic tracking of the welding parameters (AutoComp) in the event of changes in the environment, such as position errors in the welding torch, temperature fluctuations, draughts, etc. In combination with robots, for example, the Q84r can automatically adjust the welding parameters to the path speed of the welding process. With its Ethernet interface, the Q84r takes over the communication of our system with the outside world. With our PC software Q8Tool, centralised or decentralised data management and seamless welding data recording are guaranteed. The Q84r speaks fluent MQTT and OPC-UA. With an optional licence, the Q84r is able to record welding data completely internally and transfer it to our Q8xRemote visualisation software.

Q84s

Q80 for 4

The Q84s enables central control of four welding units and provides the interface between man, computer and welding equipment. Its range of functions is identical to the Q80, but when controlling several robots it is more affordable than several Q80s. With its touch screen and innovative operating concept, the Q84s is clear and easy to use. Our control units calculate optimal parameters for welding processes according to the specification of basic data such as material, filler metal, wire feed speed and gas type. The Q84s masters various welding processes (I-pulse, MIG/MAG, U-pulse, KF-pulse, microMIG, TIG, TIG-pulse) with automatic tracking of the welding parameters (AutoComp) in the event of changes in the environment, such as position errors of the welding torch, temperature fluctuations, draughts, etc. In combination with robots, for example, the Q84s can automatically adjust the welding parameters to the path speed of the welding process. With its Ethernet interface, the Q84s takes over the communication of our system with the outside world. With our PC software Q8Tool, centralised or decentralised data management and seamless welding data recording are guaranteed. The Q84s speaks fluent MQTT and OPC-UA. With an optional licence, the Q84s is able to record welding data completely internally and transfer it to our Q8xRemote visualisation software.

Q80

Universal control

with touch screen

The Q80 enables central control of a welding system and provides the interface between man, computer and welding equipment. With its touch screen and innovative operating concept, the Q80 is clean and easy to use. Our control units calculate optimal parameters for welding processes according to the specification of basic data such as material, filler metal, wire feed speed and gas type. The Q80 masters various welding processes (I-pulse, MIG/MAG, U-pulse, KF-pulse, microMIG, TIG, TIG-pulse) with automatic tracking of the welding parameters (AutoComp) in the event of changes in the environment, such as position errors of the welding torch, temperature fluctuations, draughts, etc. In combination with robots, for example, the Q80 can automatically adjust the welding parameters to the path speed of the welding process. With its Ethernet interface, the Q80 takes over the communication of our system with the outside world. With our PC software Q8Tool, centralised or decentralised data management and seamless welding data recording are guaranteed. The Q80 speaks fluent MQTT and OPC-UA. An optional licence enables the Q80 to record welding data completely internally and transfer it to our Q8xRemote visualisation software.

Q6pw

Perfect for local start-up

The Q6pw control unit is a budget-friendly starter solution. Our control units calculate optimal parameters for welding processes according to the specification of basic data such as material, filler metal, wire feed speed and gas type. The Q6pw can handle various welding processes (I-pulse, MIG/MAG, U-pulse, KF-pulse, microMIG, TIG, TIG-pulse) with automatic tracking of the welding parameters (AutoComp) in the event of changes in the environment, such as position errors in the welding torch, temperature fluctuations, draughts, etc. In combination with robots, for example, the Q6pw can automatically adjust the welding parameters to the path speed of the welding process.

Simplified set-up and data backup are possible with our Q8-Tool software.

Q4

Integrated LSQ control

The Q4 control unit is an integrated basic solution for the Leipold power source (LSQ). Integration in LSQ3 or LSQ5 makes the Q4 very attractively priced. Our control units calculate optimal parameters for welding processes according to the specification of basic data such as material, filler metal, wire feed speed and gas type. The Q4 can handle various welding processes (I-pulse, MIG/MAG, U-pulse, KF-pulse, µMIG, TIG, TIG-pulse) with automatic tracking of the welding parameters (AutoComp) in the event of changes in the environment, such as position errors of the welding torch, temperature fluctuations, draughts, etc. In combination with robots, for example, the Q4 can automatically adjust the welding parameters to the path speed of the welding process.

Simplified set-up and data backup are possible with our Q8-Tool software.

Q1

Manual welding controller

The Q1 welding process control is designed for manual welding tasks with Leipold power sources (LSQ). Our control units calculate optimal parameters for welding processes according to the specification of basic data such as material, filler metal, wire feed speed and gas type. The Q1 can handle various welding processes (I-pulse, MIG/MAG, U-pulse, KF-pulse, TIG, TIG-pulse with automatic tracking of the welding parameters (AutoComp) in the event of changes in the environment, such as position errors of the welding torch, temperature fluctuations, draughts, etc.

Our Q1-Tool software facilitates set-up and data backup.